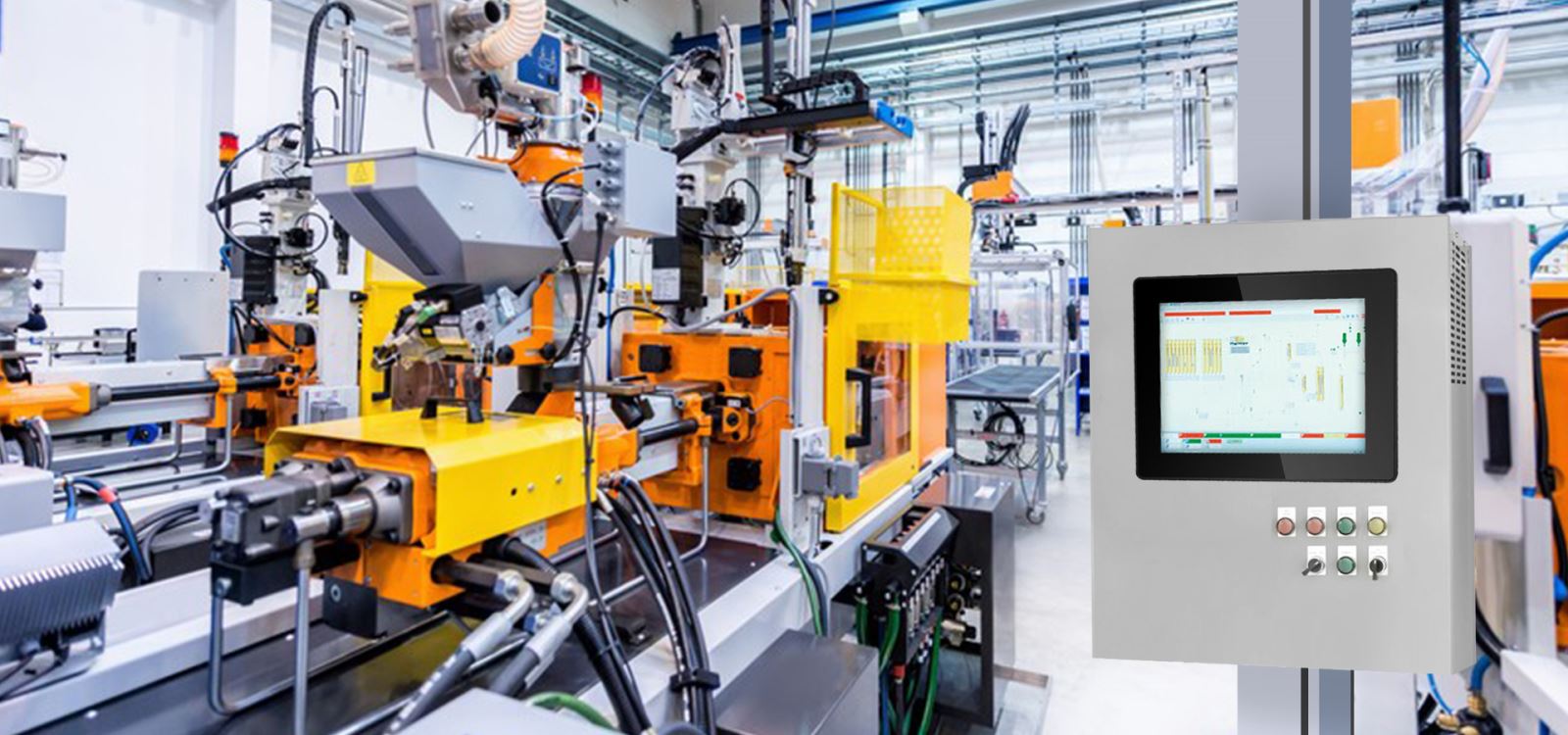

Industrial Automation

Modularized Industrial Panel PC Provide Flexibility for Automation Industry

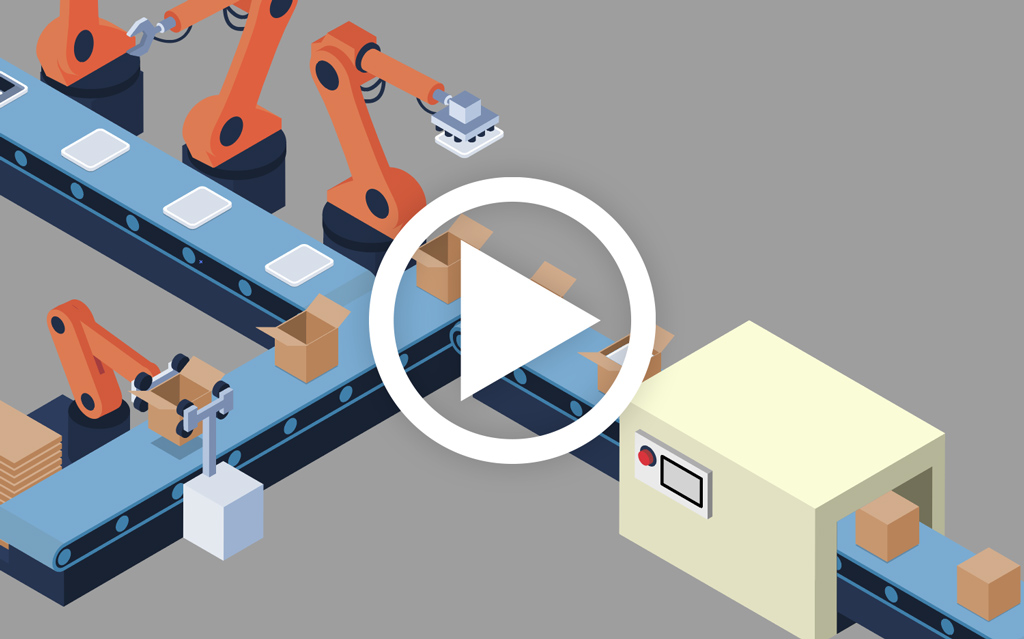

With the arrival of Industry 4.0, and the resulting shift in market demands, a rapid time-to-market and customer responsiveness have become key concerns for the manufacturing industry. Automation systems and equipment are exceedingly powerful, but can become quite complex to deliver all of the required features and functionality. There is a continuing push in industry for methods, equipment and systems which are more open and modular. End users have expressed their displeasure at the way automation systems have evolved … they want a solution built on modular, standardized elements that can be easily integrated together.Qunlink Modularized Industrial Panel PCs fit this vision.

Box PCs configured as all-in-one units with integral displays are very attractive from an installation standpoint because they fit nicely into constrained locations.The obvious downside is that any failure, and many types of performance upgrades, require a complete replacement of the in-service unit. This is costly, introduces challenges with maintaining spare parts, and can extend repair times. Users have looked for a better option.

Modularized Industrial Panel PC

Qunlink creats Modularized Industrial Panel PCs, where users can select from a range of available display modules and box modules. In particular, Qunlink’s Modularized Industrial Panel PCs easily allows users to concoct the exact automation PC/display unit to meet their needs. The PCs package is optimized for easy installation, and if needs change it is a snap to modify the configuration. End users can stock a reduced subset of parts, and also benefit from minimal downtime if a repair or upgrade is needed. Performance is improved while overall cost is reduced.

Modularize your platform

The innovative modular design of Qunlink's Modularized Industrial Panel PCs offers increased flexibility and updatability that allows manufacturers to more promptly respond to market demands and reduce operating costs. This modularization also enables cost-effective equipment upgrades for truly future-proof infrastructure.

Benefits of Modularization

Flexible

- More compact and cost-effective than separate box module and display

- Fewer replacement components need to be stocked

Customizable

- Can standardize on one box module as it can work with multiple displays

- Can standardize on one display as it can work with multiple box module

- Speeds up design cycle

Maintainable

- Can program the box module in an office or other remote environment,

and then plug it into the display on the plant floor - Can replace the box module if it fails and the display doesn’t

- Can replace the display if it fails and the box module doesn’t

- Makes maintenance easier

Upgradeable

- Can upgrade the box module and continue using the same display

- Can upgrade the display and continue using the same box module

.jpg)